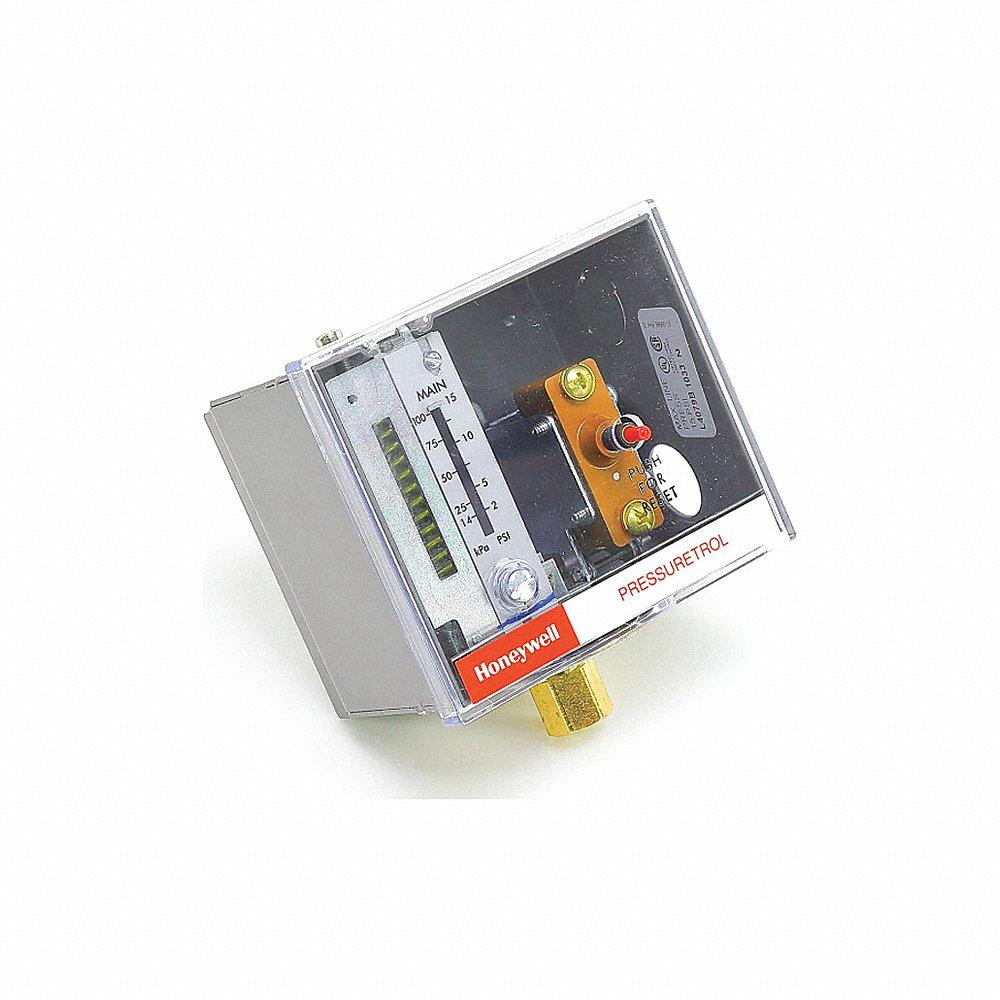

HONEYWELL Interruptores de presión y vacío Diseñado para abrir/cerrar rápidamente el circuito cuando la presión supera el punto de ajuste designado. Cuenta con una carcasa de poliéster reforzado con fibra de vidrio para mayor durabilidad y un actuador de diafragma para detectar el cambio de presión. Disponible en variantes estándar y de acción inversa.

Diseñado para abrir/cerrar rápidamente el circuito cuando la presión supera el punto de ajuste designado. Cuenta con una carcasa de poliéster reforzado con fibra de vidrio para mayor durabilidad y un actuador de diafragma para detectar el cambio de presión. Disponible en variantes estándar y de acción inversa.

Interruptores de presión

| Estilo | Modelo | Precio | |

|---|---|---|---|

| A | L4079B1033 | €357.00 | |

| B | C6097A3004 | €301.00 | |

| C | 76055-00001000-01 | €164.93 | |

| D | C6097A3012 | €331.75 |

Interruptor de presión

Los interruptores de presión de Honeywell se utilizan para proporcionar retroalimentación eléctrica en respuesta a una cámara que sube o baja a un nivel de presión predeterminado. Estas piezaes cuentan con un gabinete de poliéster reforzado con vidrio con una conexión de terminal de tornillo capaz de ajustes de campo y un diafragma Kapton compatible para usar con una amplia variedad de fluidos. Además, están diseñados para funcionar en conjunto con diferentes terminaciones (conector Metri-Pack) que forma un sello hermético cuando se conecta. Elija entre una amplia gama de estos interruptores de presión disponibles en variantes de presión de rotura de 750 psi y 1250 psi en Raptor Supplies.

Los interruptores de presión de Honeywell se utilizan para proporcionar retroalimentación eléctrica en respuesta a una cámara que sube o baja a un nivel de presión predeterminado. Estas piezaes cuentan con un gabinete de poliéster reforzado con vidrio con una conexión de terminal de tornillo capaz de ajustes de campo y un diafragma Kapton compatible para usar con una amplia variedad de fluidos. Además, están diseñados para funcionar en conjunto con diferentes terminaciones (conector Metri-Pack) que forma un sello hermético cuando se conecta. Elija entre una amplia gama de estos interruptores de presión disponibles en variantes de presión de rotura de 750 psi y 1250 psi en Raptor Supplies.

| Estilo | Modelo | la columna Acción | Presión de rotura | Formulario De Contacto | Configuración de encendido / apagado de fábrica | NEMA | Gama de Colores | Precio | |

|---|---|---|---|---|---|---|---|---|---|

| A | 76575-B00000040-01 | €125.44 | |||||||

| A | 76052-B00000150-01 | €124.18 | |||||||

| B | 76054-B00000600-01 | €127.63 | |||||||

| A | 76051-B00000020-01 | €115.97 | |||||||

| A | 76053-B00000300-01 | €126.29 | |||||||

| A | 76055-B00001000-01 | €128.27 | |||||||

| A | 76576-B00000100-01 | €118.30 | |||||||

| B | 76064-B00000600-01 | €157.70 | |||||||

| B | 76061-B00000020-01 | €136.33 | |||||||

| A | 76577-B00000040-01 | €138.65 | |||||||

| A | 76580-B00000100-01 | €143.22 | |||||||

| A | 76072-B00000150-01 | €164.52 | |||||||

| A | 76074-B00000600-01 | €148.96 |

Caracteristicas

- Honeywell pressure switches feature a glass-reinforced polyester enclosure for durability and a diaphragm actuator to sense the pressure change.

- These units have a Kapton diaphragm compatible for use with a wide variety of fluids.

- They are further designed to work in conjunction with different terminations (Metri-Pack connector) which forms a tight seal when connected.

- They are available in 750 PSI and 1250 psi burst pressure variants.

Mecanismo de trabajo

- Apply pressure or vacuum to the sensing element.

- Sensing element deforms in response to pressure or vacuum.

- This causes the movement of a diaphragm or piston and activates a switch mechanism.

- The switch mechanism then completes or interrupts an electrical circuit based on the pressure or vacuum level.

- Finally, the electrical circuit controls associated equipment or triggers alarms.

Preguntas frecuentes

How do I install Honeywell pressure and vacuum switches?

- Securely mount the switch using appropriate fasteners, ensuring it is positioned correctly.

- Connect the electrical wiring to the terminals of the pressure or vacuum switch according to the wiring diagram provided.

- Test the operation of the switch to ensure it functions correctly and responds appropriately to changes in pressure or vacuum.

- If required, adjust the switch settings according to the application requirements.

- Once tested and adjusted, securely fasten any connections and ensure they are properly insulated.

- Conduct a final inspection to verify that the switch is installed correctly and is ready for use.

What factors should I consider while choosing a pressure and vacuum switch?

- Select a switch with the necessary accuracy to meet your operational requirements.

- Determine if the switch allows for easy adjustment of setpoints to accommodate varying pressure or vacuum levels.

- Consider the response time of the switch to ensure it reacts quickly to pressure or vacuum changes as needed.

- Assess the operating environment for factors such as temperature, humidity, and exposure to corrosive or hazardous substances, and choose a switch that can withstand these conditions.

- Ensure the switch's electrical rating matches your system requirements to prevent overload or failure.

- Choose a switch with mounting options suitable for your application, whether it's panel mount, pipe mount or other configurations.

- Select a switch from a reputable manufacturer known for producing reliable and durable products to minimise the risk of failure.

- Check if the switch meets industry standards and certifications relevant to your application, such as UL, CE or CS

What safety precautions should I take while using a pressure and vacuum switch?

- Operate the switch within specified temperature, humidity and environmental conditions outlined in the manual to prevent damage or malfunction.

- Follow electrical safety procedures when connecting the switch to power sources, such as turning off the power before installation, using insulated tools and wearing appropriate personal protective equipment.

- Do not exceed the maximum pressure or vacuum rating of the switch to prevent damage or failure.

- Periodically inspect the switch for signs of damage, wear or corrosion and replace any worn or damaged components promptly.

- Establish procedures for emergency shutdown in case of switch malfunction or unexpected pressure / vacuum conditions.

¡Estamos aquí para ayudar!

¿Busca una pieza que no figura aquí?

Conozca Más

- Filtración

- Formación

- Insecticidas y control de plagas

- Ventilación

- Paneles solares y accesorios

- Bandejas de drenaje y goteo

- Sistemas de monitoreo inalámbricos

- Herramientas de alivio de hilo

- Detectores y accesorios de remolques para montacargas

- Enfriadores de aceite de aire forzado fuera de línea

- ACCUFORM SIGNS Etiqueta de peligro, cartulina PF de 10 mil, 5-3 / 4 "x 3-1 / 4"

- WESCO Carros de servicio de acero

- RULE Bomba sumergible

- ELVEX Serie RX-200, anteojos de lectura

- COOPER B-LINE Conducto de la serie Guide Rite a soportes de pedestal

- WESTWARD Conjunto de tapón, 1/4s

- TB WOODS Acoplamientos de disco flexible serie D

- VESTIL Bases opcionales de la serie JIB-CB

- TRI-ARC Escaleras enrollables perforadas para selección de stock

- SPEEDAIRE Placas traseras